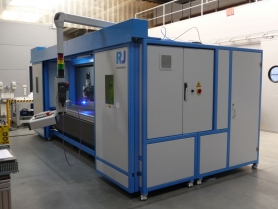

Laser cutting machine for large components up to 2500 mm in length

This was the job:

Construction of a large laser fine cutting system for precision cuts up to a length of 2500 mm and width of 500 mm for universal use in the service sector.

This is how we solved it:

A pulsed fibre laser with 450 W average power and 4500 pulse power as well as high beam quality (50 µm multimode fibre optic) was selected as the laser source. This means that the finest contours from 0.05 mm up to 5 mm wall thickness could be laser cut.

The X and Y axes are driven by linear motors and positioned by high-resolution measuring systems. The dynamics lie in the movement of the axes at an acceleration value of about 1 g. A contour accuracy of 20 µm and better is achieved in the entire machining area.

The processing head of the laser cutting system is moved over the workpiece at the pre-selected nozzle spacing using a capacitive distance sensor, thus generating a consistently high quality of cut.

All metallic materials and selected technical ceramics can be processed on the system.

In this set-up, the fine-blanking system certainly represents a unique selling point in universal use and offers new possibilities in the precision cutting of large-format workpieces.

In this special configuration, the system is unique for universal machining use and offers a wide range of new possibilities in the precision cutting of large-format workpieces.

The result:

Complete in its conception, easy to use and yet complex in terms of processing options.

Automatic service door, shielded drive technology and the latest CNC technology.

Customer:

Limab GmbH